OUR WORK IN ACTION

RECENT PROJECTS

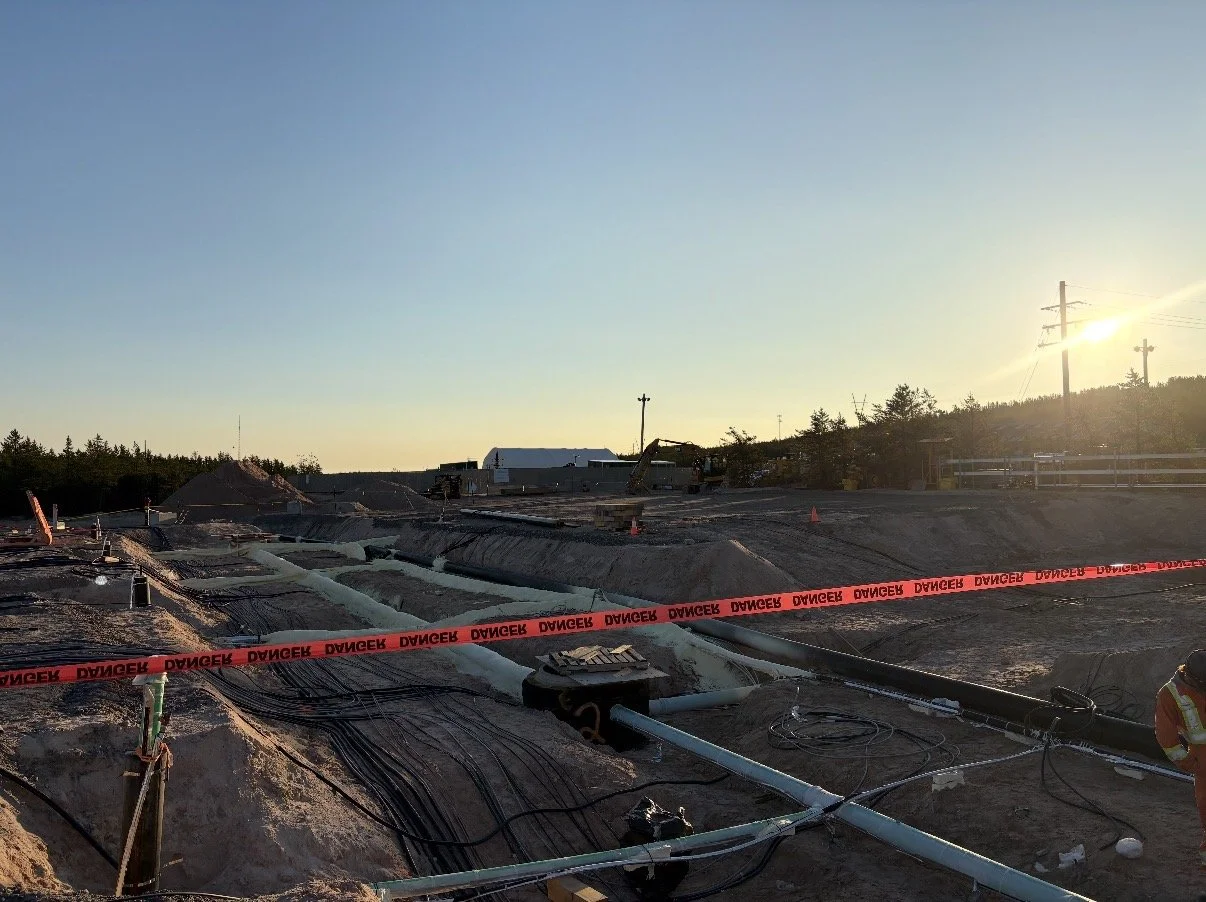

KEY LAKE MINE

2025

Insulated and supported shallow-buried piping following extensive delays in delivery of factory-insulated pipe. After consultation with the client’s engineering team, we were engaged to complete the work, including additional foam support beneath the pipe where native ground compaction could not meet requirements. The entire scope was completed in three days, offering a significantly faster and safer alternative to traditional methods.

TRANS MOUNTAIN PIPELINE

2022 - 2024

Supported Section 5 alongside multiple contractors, installing over 300 foam breakers and plugs, along with rock guard protection in rocky terrain. Also supplied pre-manufactured foam pillows using a custom-spec foam tailored to the client’s performance criteria.

OVINTIV - PIPESTONE WELD JOINTS

2024 - 2025

Supplied and installed foam insulation for over 4,000 weld joints ranging from 6” to 12” pipe diameters. Foam products and application procedures complied fully with CSA Z245.30 standards. Foam pillows and select pipe support structures were also installed as part of the scope.

COASTAL GASLINK PIPELINE

2020 - 2021

Executed work on various sections throughout 2020 and 2021, installing more than 250 breakers and plugs. Close coordination with the client ensured all foam applications were performed to exact specification and engineering requirements.

HIGH PINE EXPANSION

2017 - 2018

Completed installation of over 160 ditch plugs and breakers across multiple steep gradients, including areas exceeding 60% slope. The project utilized specialized skid-mounted units in combination with wheeled equipment. Additionally, custom foam pillows were sprayed in place ahead of pipe lowering to ensure proper bedding and protection.

SEKUNKA HILL

2016

Delivered and installed more than 800 cubic meters of foam across a challenging slope profile. Breakers were expertly placed and contoured to achieve a 0-degree finish, ensuring stability and long-term performance.